Pros & Cons of Different Tire Tread Patterns

The tire industry has come to differentiate the four types of tire tread patterns: symmetrical, directional or unidirectional, asymmetrical, directional and asymmetrical. Also known as tire designs due to the differences in the construction of the continuous ribs, grooves, independent tread blocks, and sipes, each tire pattern better suits certain driving needs and styles.

Why Tires Have Treads

Tires are designed to have different tread depths and patterns which helps people to drive comfortably and safely. Treads on regular car tires provide stability to the vehicle when driving on different surfaces.

Grooved treads scatter and channel water from beneath the tires when driving on wet surfaces. This dispersion reduces the probability of hydroplaning on slippery roads. Treads allow the tires to retain a firmer grip on the road surface, especially when driving on soft surfaces like sand, dirt, or mud.

Correct sizing of treads on the tire improves traction, which translates to ease of handling and steering. Additionally, the grooves absorb the noise and dissipates the heat that builds up due to frictional contact between the tires and the road surfaces.

The longevity of the tires depends on the depth and design of the treads. The tire tread patterns are designed to offer maximum resistance to wear and tear. Tires without treads, such as those for racing cars have a shorter service life, compared to regular tires which are deeply grooved.

Types of Tire Tread Patterns

Directional Tread Patterns/ Unidirectional

Tires with directional tread patterns roll in only one direction. These tires have a V-shaped tread pattern, which increases the dispersion of surface water, boosting resistance to hydroplaning. These tread patterns have better traction capabilities, making them suitable for high speed driving.

This tread pattern is predominant with high-performance tires and often has an arrow on the sidewall indicating the rolling direction for easy mounting on a vehicle.

Tires having this type of tread are only limited to front-to-back or back-to-front rotation. Wrong orientation of the V’s will render the channels ineffective.

Symmetrical Tire Tread Pattern

This is the most common tread pattern designed with continuous ribs or independent tread blocks covering the entire tire. The patterns appear as a mirror on both halves of the tire. They are best suited for passenger vehicles, providing excellent handling characteristics.

Symmetrical tires have low resistance to rolling, high directional stability and constitute smoother rides. These tires are preferable for their fuel efficiency,unlimited rotation and they last longer.

The key disadvantage is that the tread patterns are poorly adapted to changes in road conditions. They become ineffective on wet road surfaces.

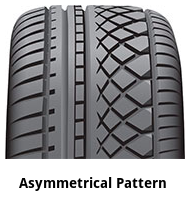

Asymmetrical Tire Tread Pattern

This type of tire features two distinct tread patterns. The inner half will possess a unique tread pattern as compared to the tire’s outer half. The inner tire tread pattern is designed to scatter water on the road surface, protecting the vehicle from hydroplaning. The outer tread pattern has rigid tread blocks which raises the tire’s lateral stiffness.

Increased lateral stiffness provides better traction when cornering and reduces the noise levels due to frictional contact. Asymmetrical tires provide excellent handling with excellent curve stability, making them popular with ultra-high performance vehicles.

These tires can only be rotated in the front-to-back or back-to-front orientation as the treads are designed to roll in one direction. They also tend to wear at faster rates and are costlier.

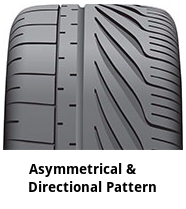

Directional and Asymmetrical Tire Tread Pattern

Designed for high-performance vehicles like sports cars, this type of tire tread pattern is quite a rare beast and usually hard to find and very expensive. The technology of directional V-shape pattern effectively withdraws the water. Due to the specific usage, there are strict rules for exploitation.

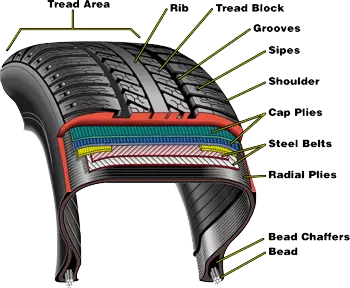

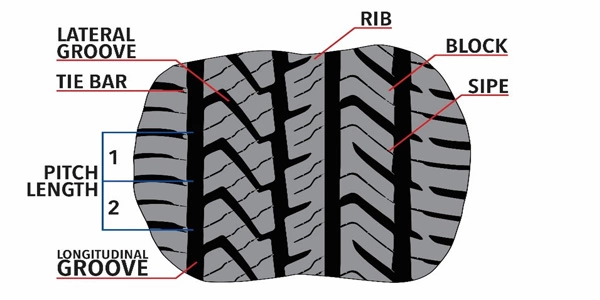

Tread Pattern Anatomy

Tread patterns are multiple features molded on the circumference of the tire. The tire tread pattern may include several ribs, blocks, lugs or a combination of all three.

Ribs

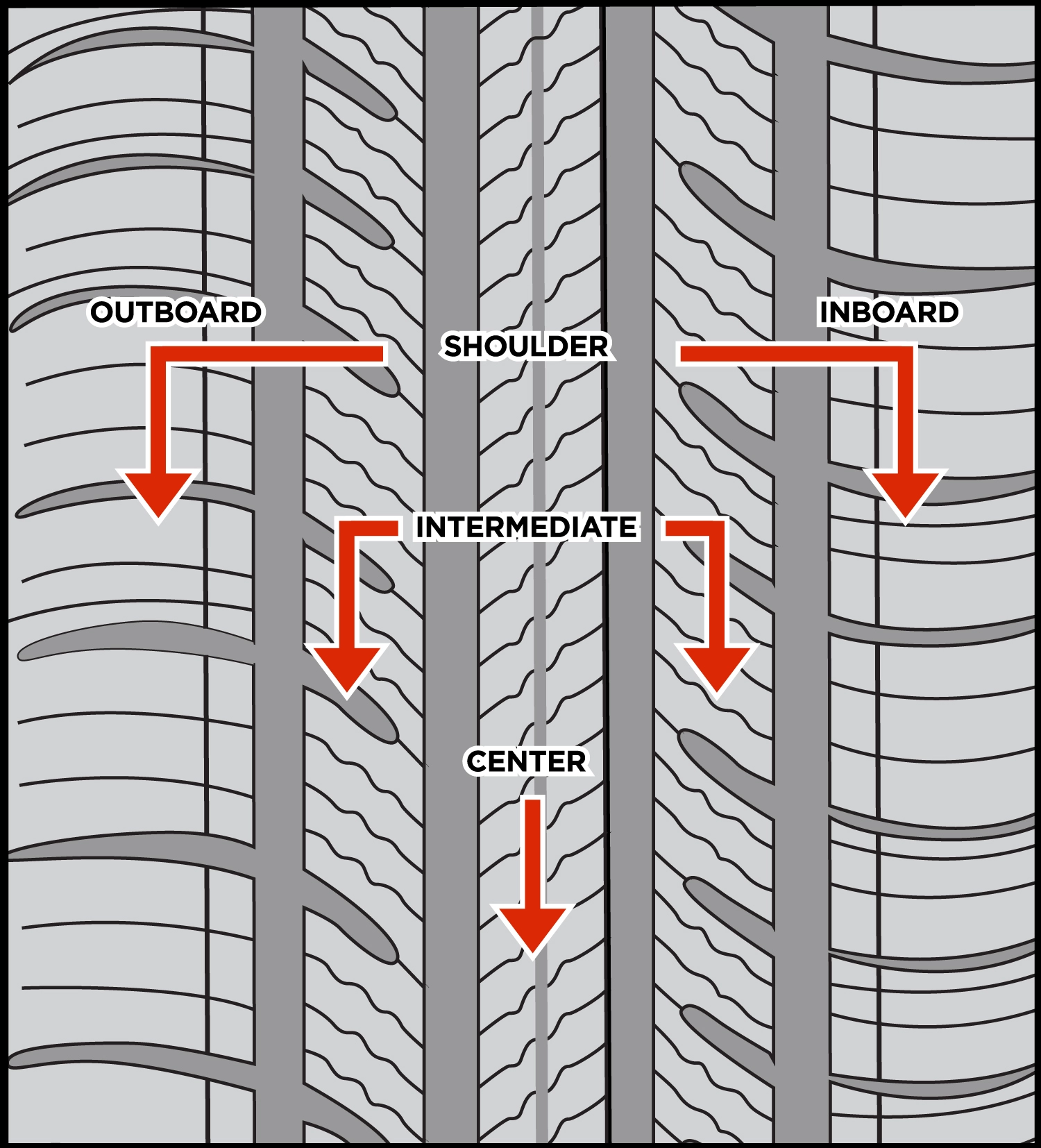

Ribs are the continuously raised sections of the tread that come into direct contact with the road surfaces. A tire’s rib includes:

- Outboard shoulder, which is the structure that handles the lateral stresses exerted on the tire when negotiating corners. The outboard shoulder is the outermost edge of the tire’s tread, extending between the sidewall and the footprint of the tread.

- Outboard intermediate is the rib section that’s adjacent to the outboard shoulder. The rib section absorbs excess lateral stresses making it the second fastest section to wear out due to cornering.

- Center is the rib section that provides stability when accelerating in a straight direction along the road. The rib center provides enough traction while braking.

- Inboard shoulder is the inward section of the tread which extends between the inner tire sidewall and the tire’s tread footprint. It usually experiences the lowest lateral stresses when cornering. They are however prone to rapid wear and tear, especially if the tires have negative camber.

- Inboard intermediate is the rib section, lying between the rib center and the inboard shoulder.

Tread Blocks

Tread blocks are individual pieces of rubber that are slightly taller than the rest of the tread patterns. They appear in rows, arranged alongside each other around the circumference of the tire.

Lugs

They are large, freestanding tread blocks that are spread across the tire’s circumference and common with light truck tires.

Grooves

They are deep cuts that run at different angles depending on the tread pattern. They allow the rubber to flex, making it possible to drive on rough surfaces without damage to the tire.

Circumferential grooves

These are the deepest grooves around the tire, responsible for scattering water under the tires over wet surfaces.

Lateral grooves

These are grooves that are molded across the tire surface and significantly increase braking traction and acceleration

Tie bars

They are short rubber links between lateral grooves that connect adjacent tread blocks.

Sipes

These are thin and small cuts made along tread blocks to provide additional traction and stability when driving over wet surfaces or soft grounds.

FAQ

How do tire treads work?

They push water, mud or soft matter from the road surface, helping the vehicle to maintain contact with the ground, helping the vehicle to accelerate in the desired direction.

What is the best tire tread pattern?

The choice of tire tread patterns vary depending on the driving conditions. A good pattern has to offer excellent traction, safety and minimal resistance to rolling, translating to improved fuel efficiency.

Is it OK to have two different tire treads?

High performance vehicles need to have excellent traction and curve stability. It is therefore important to have different sets of treads, which will protect the vehicle from skidding while providing sufficient lateral stiffness for high speed cornering.